Products

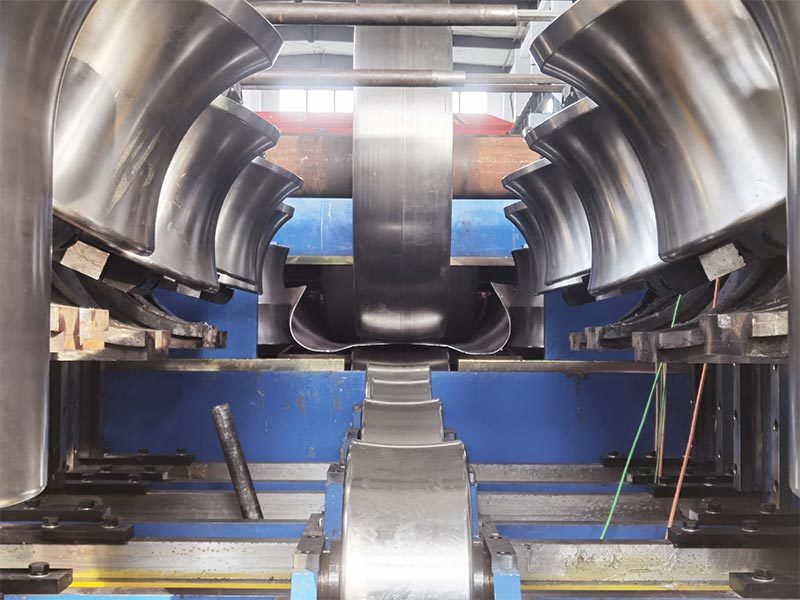

RT530 Huge Pipe welding line

※ Multi-function! Save 60% Rollers!

Category:

Product Parameters

RT530×13 high-frequency longitudinal welded pipe production line is mainly used for the production of round pipe φ219~φ530mm, wall thickness 4.0~13.0mm, square tube 170×170 - 400×400mm, wall thickness 4-10mm, and rectangular tube 260×130 - 400×200mm, wall thickness 4-10mm.

|

It adopts high-frequency induction welding and straight seam welding. Its working principle: weld the edge of the pipe when heated in a magnetic field, and then compress the edge in automatic mode, and the pipe moves continuously along the production line. This ERW high-frequency welding pipe mill is specialized equipment to produce high frequency straight seam welded pipes for structural pipe and industrial pipe. Through optimization design, best materials choice, and accurately fabrication and rolls, the whole line can be reached high precision and high speed. Within suitable range of pipe diameter and wall thickness, pipe production speed can be adjusted. The pipes is mostly used for petroleum, Natural gas, city gas, pipe network, chemical industry, electricity, steel truss, water and gas pipe line; it is widely used for a variety of pressure pipelines. |

|

Advantages

※ No need to change roller for rough forming (brake-down section)

※ Save 60% cost on rollers

※ Cuts down production time

※ Easy to repair rollers

※ Convenient to repair and adjust rollers

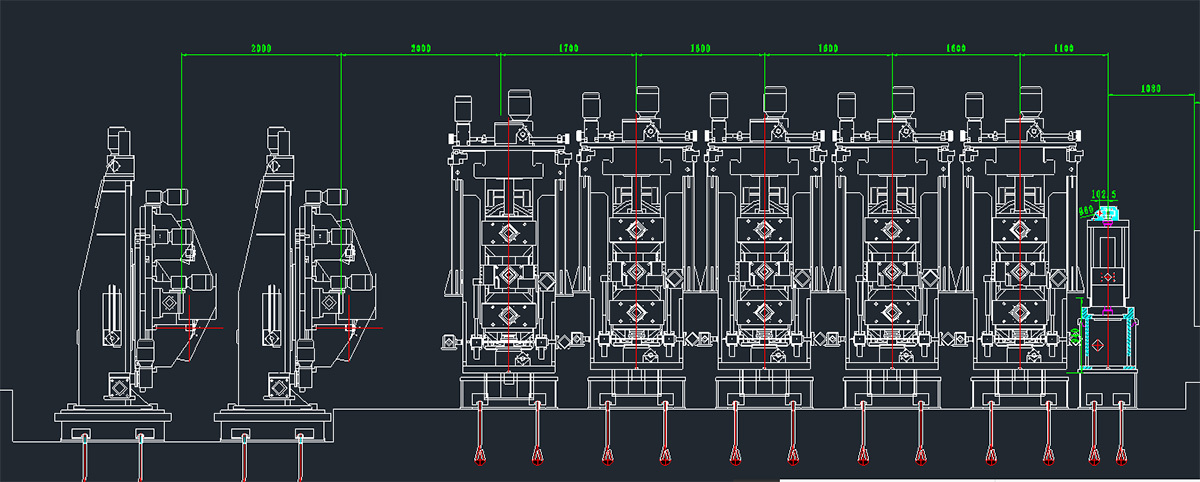

※ With Quick change system for each station for fin-pass of forming and sizing unit

Process Flow

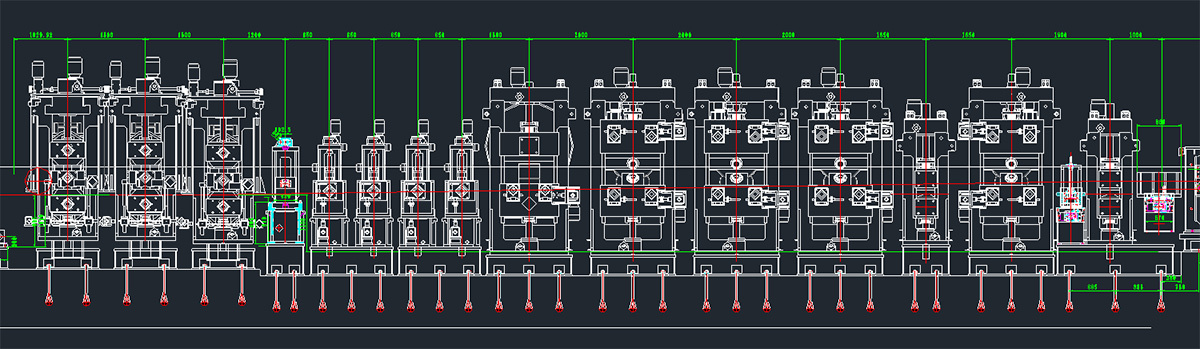

Coil strips → coil car → uncoiler → snubber roller → pinch roll and leveler → automatic shear and butt welder → horizontal spiral accumulator → side guide device → edge trimming device → scrap chopping device → ultrasonic testing unit (for plate) → feeding device → forming unit → high frequency welding unit → deburring device (inside and outside) → grinding unit → ultrasonic testing unit (for pipe) → intermediate frequency annealing for welding seam → air cooling → water cooling → sizing unit → straightening unit → CNC milling saw → roller conveyor → straightening machine → chamfering machine → hydrostatic test → (manual inspection → repair) → Measuring and weighing and label printing → auto stacking and packing (with weighing) → warehousing

|

|

Working |

Quick Change |

|

|

|

Technical Parameter

|

Raw material requirements |

|

|

Material thickness |

4.0~13.0mm (Q355); 4.0~11.0mm (X70) |

|

Yield point |

σs≤550MPa |

|

Tensile strength |

σb≤700Mpa |

|

Coil width |

650~1660mm |

|

Coil inner diameter |

610mm / 760mm |

|

Coil outer diameter |

1600-2200mm |

|

Coil weight |

Max.35T |

|

Output product scope |

|

|

Round pipe size |

φ219~φ530mm |

|

thickness |

4.0~13.0mm (Q355); 4.0~11.0mm (X70) |

|

square tube |

170×170 - 400×400mm (4-10mm) |

|

rectangular tube |

260×130 - 400×200mm (4-10mm) |

|

Producing length |

12m |

|

Cutting length precision |

±3mm |

|

Machine consumption |

|

|

Power supply |

380V/50HZ (customized) |

|

Control voltage |

AC110V/50HZ |

|

Gear oil |

N460 |

|

Hydraulic oil |

L-HM46 |

|

grease |

Calcium base grease No. 2 |

|

Power |

Appro. 5500KW |

|

High frequency power |

1200KW |

|

CO2 welder |

100KW |

|

Line data |

|

|

Total line length |

About 510m |

|

Line speed |

10~35m/min |

Key words:

ERW Carbon Steel Tube Mills

Pipe welding line

pipe making machine

Related Products

Get a Free Product Quote