Products

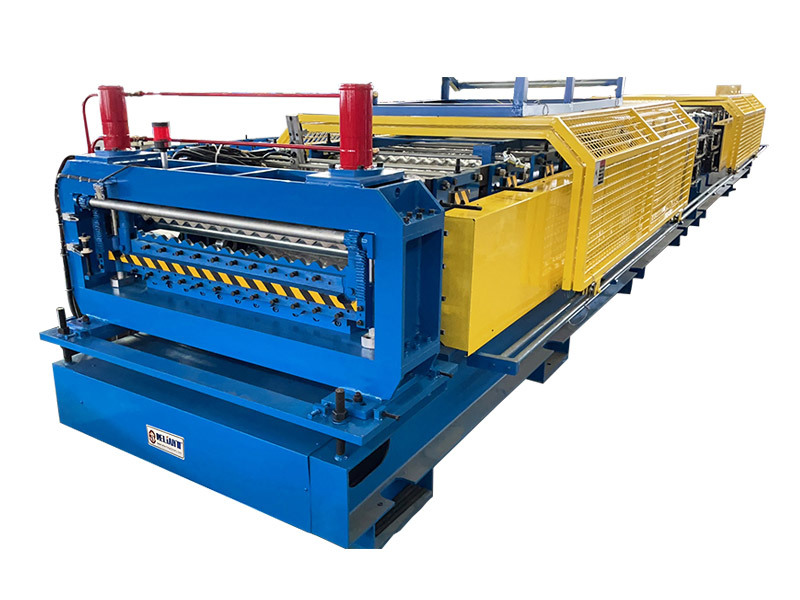

Double Layer roll forming

※ Compact Design! Save Cost and Space!

Category:

Product Parameters

The double layer roll forming machine is designed to save the machine cost and installation space. They are mostly suitable for the roofing panel and wall panels in trapezoidal and corrugated shape. The operation to change the dual-level is by clutch, easy operation and maintenance. The build-in hydraulic station make the machine structure compact also.

|

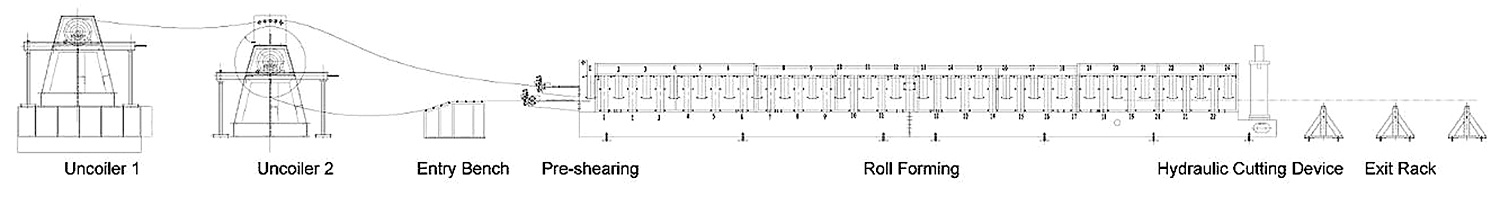

For this kind of dual-leveler roll former, it is mainly composed of the uncoiler+ coil cars, main forming sections (including entry parts: entry bench, pre-cut, film-on device, side guide unit etc), hydraulic cutting and simple run-out table (exit rack), and the auto stacker machine is optional when in need. This kind of cold roll forming machine is widely used for making various metal wall panels and roof panels for steel constructions, steel structure projects and containment systems etc. |

|

Photos for reference

|

|

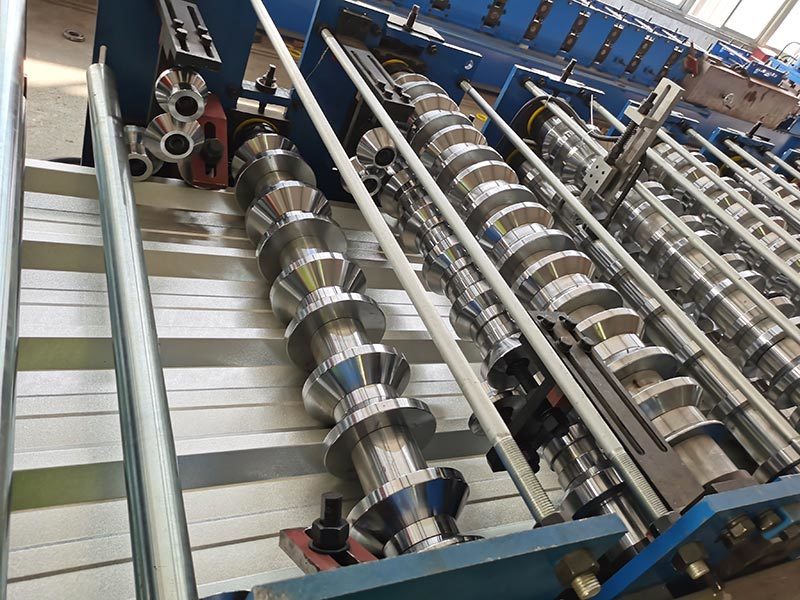

Forming Section |

Cut off and Exit Rack |

Flow Chart

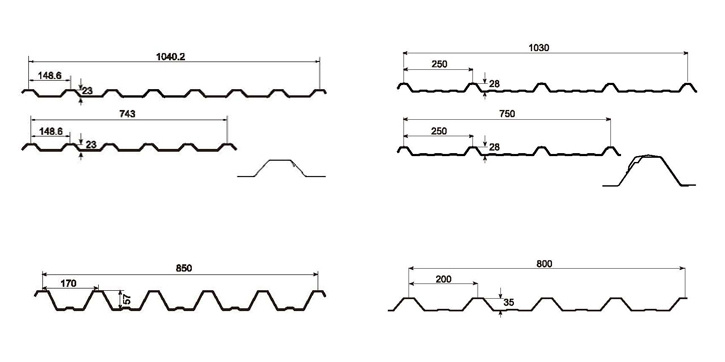

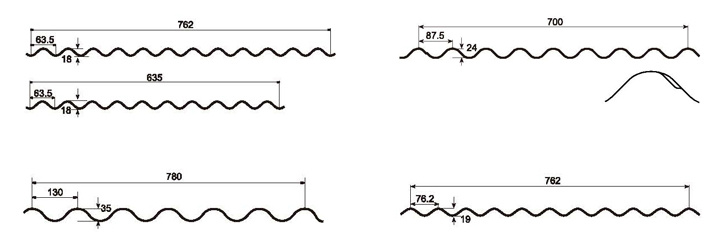

Profile Drawing

Technical Parameter

|

Item |

unit |

Parameter |

Remark |

|

|

Applicable material |

Type |

|

Color plate, aluminium sheet, galvanized plate |

Depending on customers' requirement |

|

Thickness |

mm |

0.25-0.45/ 0.3-0.5/ 0.4-0.6/ 0.5-0.8/0.75-1.0 |

||

|

Yield strength |

Mpa |

230-300/ 350/550-675 |

As per customers' material characteristic |

|

|

Width |

mm |

914/1000/1200/1220/1250 |

According to different profile shape |

|

|

Coil weight |

T |

5 / 6 / 10 |

Optional |

|

|

Working speed |

m/min |

≤ 15- 30 |

According to customers' desired production capacity and requirement |

|

|

Roller material |

|

45steel, 40Cr, GCr15 or D2 |

||

|

Electric control system |

|

Industrial computer PLC frequency control |

|

|

|

Console mode |

|

Touch screen+ button |

With remote controller |

|

|

Motor Power |

|

220V/380V/415V/460V |

As requests |

|

Key words:

Construction Rollformer

Double Layer roll forming

Double Layer roll forming machine

Related Products

Get a Free Product Quote