Products

High Speed Stud Roll Forming M/C

※ High Speed! Quick Change!

Category:

Product Parameters

|

Stud roll forming machine is based on strip steel as raw material, through continuous cold rolling forming, to produce of complex section profiles (products: light steel keel, all kinds of building profiles, steel structure, steel lining door frame profiles, high-speed dry wall, etc.) with different specifications of cold bending, using PLC control. Beside the common speed 0~15m/min machines, the high speed stud machine speed is up to 60m/min with track cutting. The cassette unit can be equipped for different profiles quick change when in need of different products. Also, the double row forming machine can be choose for two profile working. |

|

Photos for reference

|

|

Forming |

Cassette Quick Change |

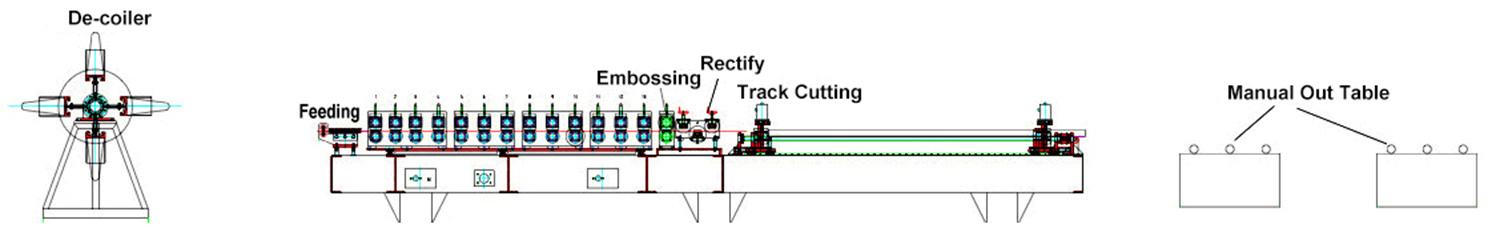

Flow Chart

Decoiler → Feeding → Roll forming → Track cutting → Run-out table

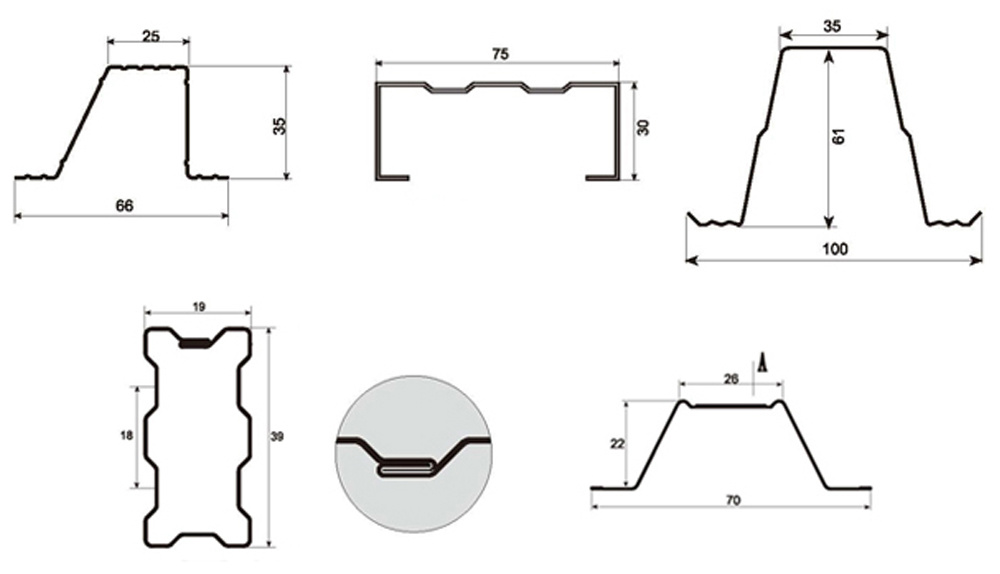

Profile Drawing

Technical Parameter

|

Item |

unit |

Parameter |

Remark |

|

|

Applicable material |

Type |

|

galvanized plate |

Depending on customers' requirement |

|

Thickness |

mm |

0.3-0.5/ 0.4-0.6 |

||

|

Yield strength |

Mpa |

230-300/ 350/550-675 |

As per customers' material characteristic |

|

|

Width |

mm |

TBD |

According to different profile shape |

|

|

Coil weight |

T |

3 / 5 |

Optional |

|

|

Working speed |

m/min |

60 |

According to customers' desired production capacity and requirement |

|

|

Roller material |

|

45 steel, 40Cr, GCr15 or D2 |

||

|

Electric control system |

|

Industrial computer PLC frequency control |

|

|

|

Console mode |

|

Touch screen+ button |

With remote controller |

|

|

Motor Power |

|

220V/380V/415V/460V |

As requests |

|

Key words:

Construction Rollformer

High Speed Stud Roll Forming Machine

Stud Roll Forming Machine

Related Products

Get a Free Product Quote