Products

Floor Deck Forming Machine

※ High Efficiency ! Cassette Quick Change!

Category:

Product Parameters

Floor decking roll forming line speeds up to 25m/min with high efficiency, it is possible to produce various profiles through add cassette quick-change unit.

The whole steel deck forming line can be controlled by remote controller, integral guard was covered on the machine, which complying with European Unions safety standards and has been passed CE.

|

|

The steel deck panels produced by the cold roll forming machine features a simple design, high ribs, high strands, and specially used in high story building and the large or medium-size industry or civilian construction. |

Photos for reference

|

|

Cutting |

Auto Stacker |

Cassette Quick Change |

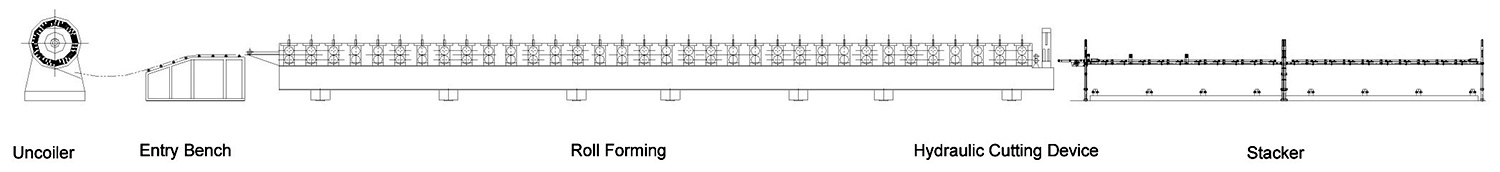

Flow Chart

Uncoiler --- feeding ---- roll forming --- hydraulic cutting --- stacker

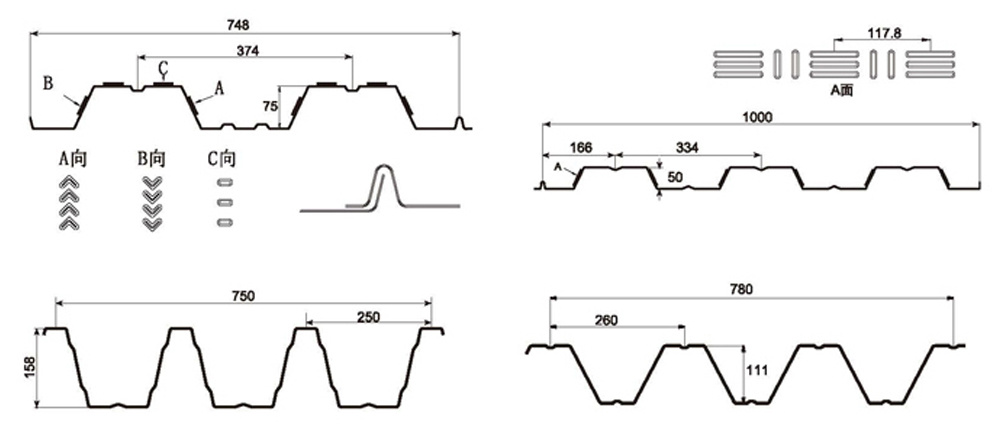

Profile Drawing

Technical Parameter

|

Item |

unit |

Parameter |

Remark |

|

|

Applicable material |

Type |

|

galvanized plate |

Depending on customers' requirement |

|

Thickness |

mm |

0.5-1.0 / 0.8-1.2 |

||

|

Yield strength |

Mpa |

230-300/ 350 |

As per customers' material characteristic |

|

|

Width |

mm |

914/1000/1220/1250 /1500 |

According to different profile shape |

|

|

Coil weight |

T |

10 /15 |

Optional |

|

|

Working speed |

m/min |

≤ 15- 25 |

According to customers' desired production capacity and requirement |

|

|

Roller material |

|

45 steel, 40Cr, GCr15 or D2 |

||

|

Electric control system |

|

Industrial computer PLC frequency control |

|

|

|

Console mode |

|

Touch screen+ button |

With remote controller |

|

|

Motor Power |

|

220V/380V/415V/460V |

As requests |

|

Key words:

Construction Rollformer

Floor Deck Forming Machine

Floor Deck Roll Forming Machine

Related Products

Get a Free Product Quote