Products

Direct Profile Lines

※ Full Automatic! Without Roll Change!

Category:

Product Parameters

This tube mill adopts a direct forming section to produce square and rectangular tubing.

|

Compared to the traditional production process (round to square), Directly Profile line (i.e. H.F directly to square, rectangle tube line) is completely automatic, easy, accurate and fast set up production process. It brings undisputed advantages in terms of flexibility, production capability and cost reduction. The automatic roller adjustment system is designed for adjusting all of the tube mill rollers. The motors installed on each stand provide this (Servo motor or AC motor +absolute encoder). Whole process is controlled by special software and operated from the control panel. |

|

Advantages

※ Save raw material width by 2~4% for same profile production

※ Meet requirements of multi-product small-batch production

※ Modify the profile dimensions without any roll change

※ Extreme reduction of set-up time for mill

※ Elimination of cost for forming rolls

※ High production capacity

※ Reduction of manpower

※ Minimal and easy maintenance

※ Easy use of software for set up production parameters

|

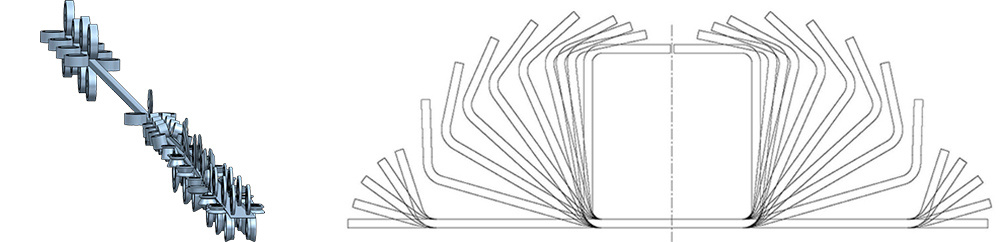

Forming Section |

Welding Section |

Cutting Saw |

Square Tubes Samples |

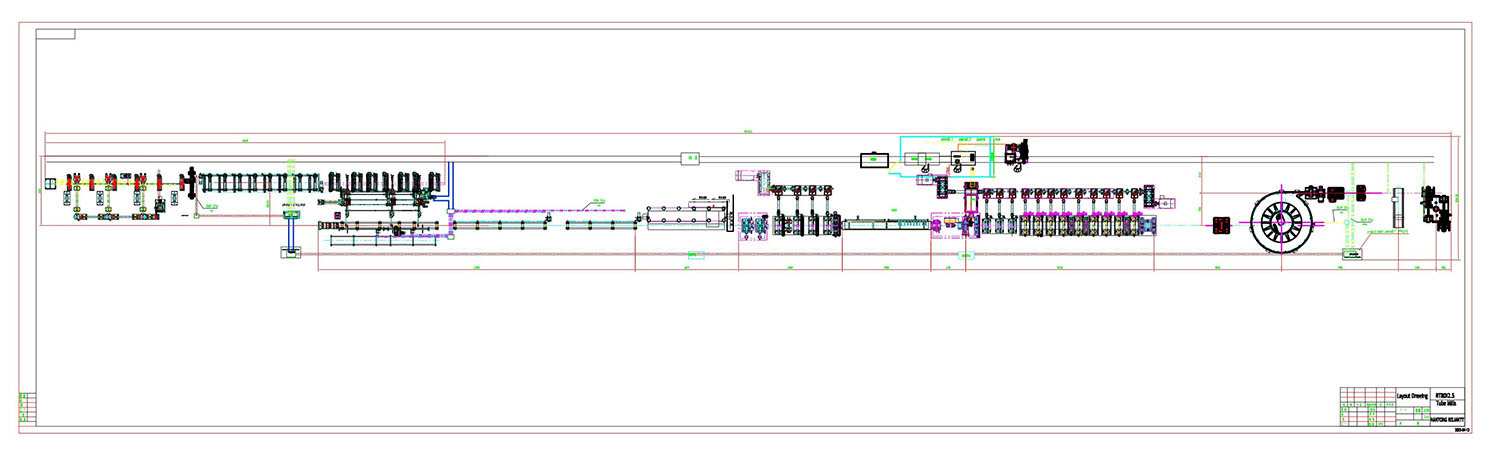

Process Flow

Raw Material (Strip Coil) → Decoiler → Snubber Roller + Pinch Roll + Leveler → Shear & Butt Welder → Horizontal Accumulator → Forming (directly forming to square or rectangle shape) → HF Welding → Scraping → Cooling → Sizing → Straightening → Cutting → Run-out→ stacking & bundling machine

Technical Parameter

|

Mode |

Square Tube Size |

Rectangular tube Size |

Tube Thickness |

Max. Speed |

Material |

|

RT80×2.5 |

30×30 - 80×80 |

30×60 - 100×50 |

0.9-2.5 |

105 |

ST-37 ; ST-52 |

|

RT100×4 |

40×40 - 100×100 |

40×60 - 120×60 |

1.5-4 |

90 |

ST-37 ; ST-52 |

|

RT120×5 |

50×50 - 120×120 |

50×60 - 140×80 |

2-5 |

70 |

ST-37 ; ST-52 |

|

RT150×8 |

60×60 - 150×150 |

60×80 - 200×100 |

2-8 |

60 |

ST-52 |

|

RT200×10 |

80×80 - 200×200 |

80×100 - 250×150 |

2.5-10 |

50 |

ST-52 |

|

RT250×12.7 |

100×100 - 250×250 |

100×120 - 300×200 |

3-12.7 |

40 |

ST-52 |

|

RT300×12.7 |

120×120 - 300×300 |

120×160 - 400×200 |

4-12.7 |

30 |

ST-52 |

|

RT400×16 |

200×200 - 400×400 |

200×250 - 450×350 |

4-16 |

25 |

ST-52 |

Key words:

ERW Carbon Steel Tube Mills

Pipe Making machine

Tube Mill

Related Products

Get a Free Product Quote