Products

Tube and Profile Lines

※ High Precision! Customization!

Category:

Product Parameters

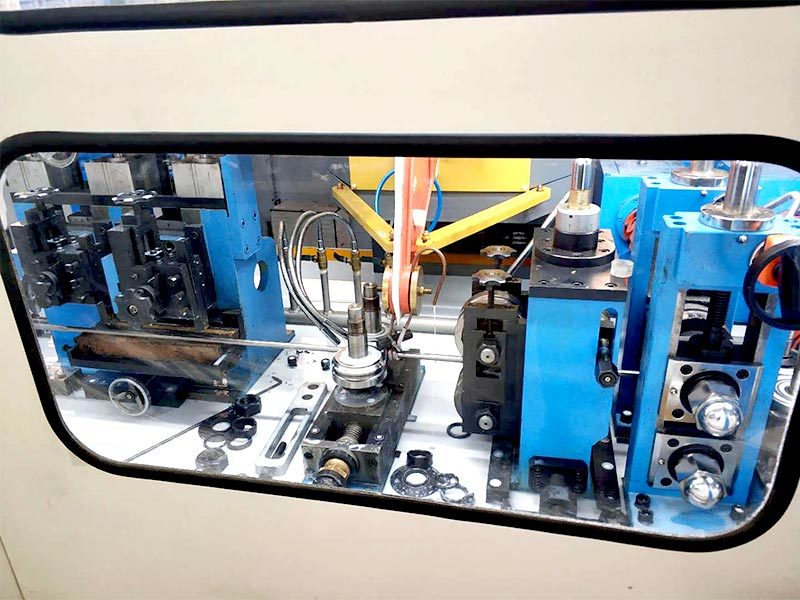

This Precision ERW tube mill line is a combination of series machines installed in a line for the production of high frequency induction welded carbon steel tubes.

The process with cold forming of carbon steel strips in circular shape, longitudinal welding, sizing, converting into specified shape and cutting to set length.

|

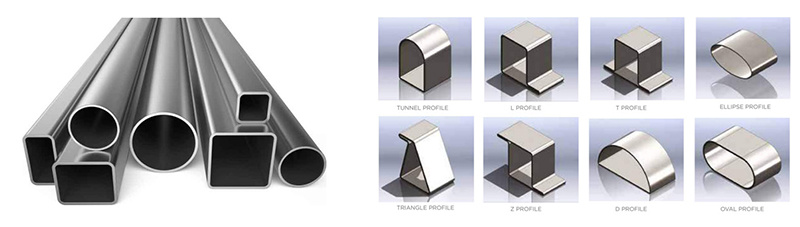

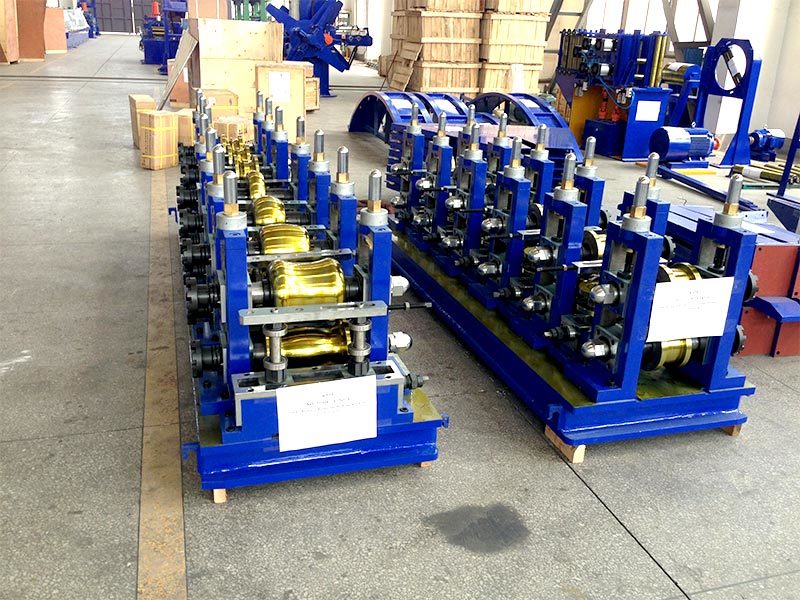

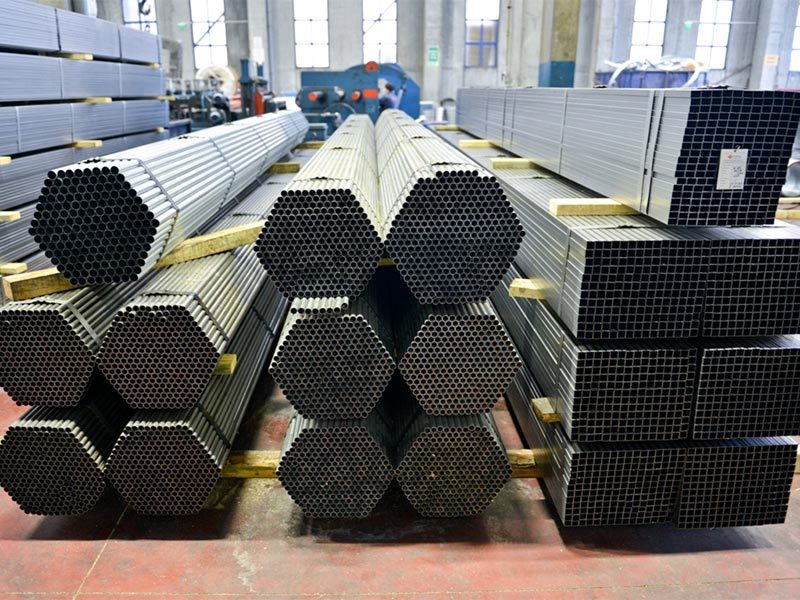

The RT series H.F straight welded pipe production line with 30+ standard models, covering range from dia. 3/8” (8mm) up to 14” (355mm) (including corresponding square and rectangle profiles) & wall thickness from 0.3mm to 12mm. We can supply the customized lines, and also can prepare and arrange customized solution into existing lines. It can be complemented by a cassette system allowing the quick tooling change during profile production. The cassette are moved inline and offline by lifting. Optional equipment for this cold formed steel welded pipe line : End facing machine, hydro tester, eddy current testing equipment, inner burr scraper, zinc spray device, stacking machine, packing machine, saw blade sharpener, straightener etc. |

|

Advantages

※ High speed, high precision, high production efficiency

※ High product yield rate, low failure rate, stable performance, low operating cost

※ Slight adjustment in horizontal and vertical stands by worm an worm wheel

※ Digital position indicators for accurate and repeated roll settings

※ PLC controlled

※ Key parts made of copper to prolong the service life

※ Multiple heat treatment implemented on key parts to improve service life

※ Advanced equipment for one-time processing the machine bed to improve accuracy

|

|

RT60 |

RT76 |

RT115 |

Cassette Quick Change |

Round Pipes And Square Tubes |

Process Flow

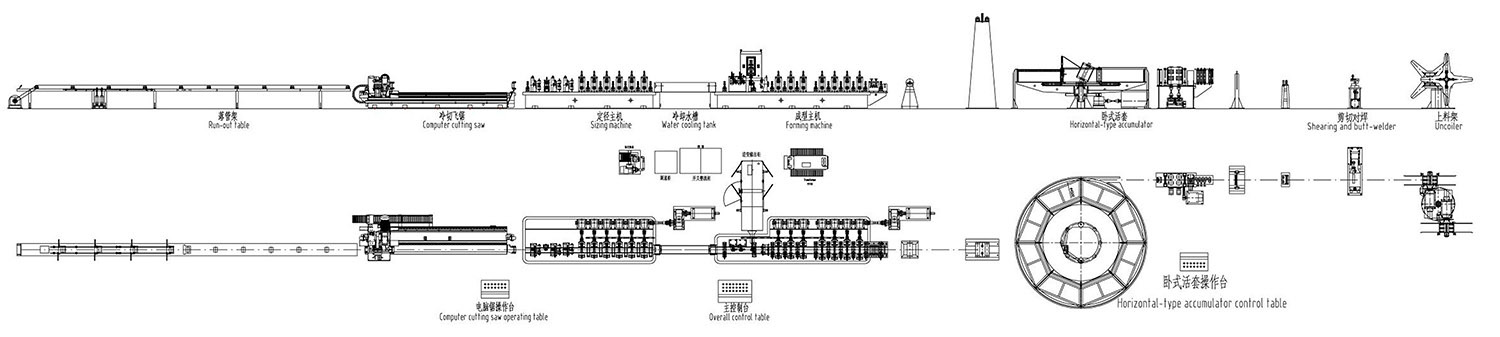

Steel strips ---- decoiler ---- shear and butt welder ---- vertical/horizontal accumulator ---- pinch roll + leveler, forming device, welding device ---- cooling unit ---- sizing and Turk’s head ---- computer saw --- run out rack

Technical Parameter

|

Model |

Production sizes |

Walll thickness |

Speed |

Major motor power |

HF power |

||

|

round pipes |

square tubes |

round pipes |

square tubes |

||||

|

RT16 |

8-25mm |

8x8-20x20mm |

0.3-1.0mm |

0.3-0.8mm |

30-110m/min |

37KW |

100KW |

|

RT25 |

8-32mm |

8x8-25x25mm |

0.4-1.3mm |

0.4-1.0mm |

30-110m/min |

45KW |

100KW |

|

RT25Q |

8-32mm |

8x8-25x25mm |

0.4-1.3mm |

0.4-1.0mm |

30-130m/min |

75KW |

150KW |

|

RT32 |

10-40mm |

8x8-30x30mm |

0.5-1.8mm |

0.5-1.4mm |

30-100m/min |

110KW |

150KW |

|

RT32Q |

13-40mm |

10x10-30x30mm |

0.5-1.8mm |

0.5-1.4mm |

30-130m/min |

132KW |

150KW |

|

RT32Q(150M) |

13-40mm |

10x10-30x30mm |

0.5-1.8mm |

0.5-1.4mm |

30-150m/min |

160KW |

150KW |

|

RT32 to50 |

13-50.8mm |

10x10-40x40mm |

0.5-1.8mm |

0.5-1.4mm |

30-100m/min |

110KW |

150KW |

|

RT45 |

13-50.8mm |

10x10-40x40mm |

0.6-2.3mm |

0.6-1.7mm |

30-100m/min |

132KW |

150KW |

|

RT45Q |

13-50.8mm |

10x10-40x40mm |

0.6-2.3mm |

0.6-1.7mm |

30-130m/min |

160KW |

150KW |

|

RT45Q(150M) |

13-50.8mm |

10x10-40x40mm |

0.6-2.3mm |

0.6-1.7mm |

30-150m/min |

185KW |

150KW |

|

RT45 to 63 |

19-63.5mm |

15x15-50x50mm |

0.6-2.3mm |

0.6-1.7mm |

30-100m/min |

132KW |

200KW |

|

RT50 |

19-63.5mm |

15x15-50x50mm |

0.7-2.75mm |

0.7-2.3mm |

30-100m/min |

160KW |

200KW |

|

RT50Q |

19-63.5mm |

15x15-50x50mm |

0.7-2.5mm |

0.7-2.0mm |

30-130m/min |

220KW |

200KW |

|

RT50Q(150M) |

19-63.5mm |

15x15-50x50mm |

0.7-2.5mm |

0.7-2.0mm |

30-150m/min |

250KW |

200KW |

|

RT50 to 76 |

19-76mm |

15x15-60x60mm |

0.7-2.75mm |

0.7-2.2mm |

30-100m/min |

160KW |

200KW |

|

RT50 to 76Q |

19-76mm |

15x15-60x60mm |

0.7-2.5mm |

0.7-2.0mm |

30-130m/min |

220KW |

200KW |

|

RT50 to 76Q(150M) |

19-76mm |

15x15-60x60mm |

0.7-2.5mm |

0.7-2.0mm |

30-150m/min |

250KW |

200KW |

|

RT50 to 100 |

25-100mm |

20X20-80X80mm |

0.8-2.5mm |

0.8-2.0mm |

30-90m/min |

185KW |

200KW |

|

RT60 |

19-63.5mm |

15x15-50x50mm |

0.8-3.5mm |

0.8-2.7mm |

30-90m/min |

200KW |

250KW |

|

RT60Q |

19-63.5mm |

15x15-50x50mm |

0.8-3.0mm |

0.8-2.5mm |

30-130m/min |

200KW |

300KW |

|

RT60 to 76 |

19-76mm |

15x15-60x60mm |

0.8-3.5mm |

0.8-2.7mm |

30-90m/min |

200KW |

250KW |

|

RT60 to 76Q |

19-76mm |

15x15-60x60mm |

1.0-3.0mm |

0.8-2.5mm |

30-130m/min |

220KW |

300KW |

|

RT60 to 100 |

22-100mm |

20x20-76.2x76.2mm |

1.0-3.0mm |

1.0-2.5mm |

30-80m/min |

220KW |

250KW |

|

RT60 to 100Q |

22-100mm |

20x20-76.2x76.2mm |

1.0-3.0mm |

1.0-2.5mm |

30-120m/min |

220KW |

300KW |

|

RT60 to 114 |

25-114mm |

20x20-80x80mm |

1.0-3.0mm |

1.0-2.5mm |

30-80m/min |

220KW |

250KW |

|

RT76 |

25-90mm |

20x20-70x70mm |

1.0-4.0mm |

1.0-3.5mm |

20-70m/min |

220KW |

300KW |

|

RT76 to 127 |

32-127mm |

25x25-100x100mm |

1.2-4.0mm |

1.2-3.5mm |

20-70m/min |

132KWx2 |

300KW |

|

RT90 |

32-127mm |

25x25-100x100mm |

1.5-4.5mm |

1.5-4.0mm |

20-60m/min |

132KWx2 |

400KW |

|

RT90 to 140 |

32-140mm |

25x25-110x110mm |

1.5-4.5mm |

1.5-4.0mm |

20-60m/min |

132KWx2 |

400KW |

|

RT90 to 152 |

48-152mm |

40x40-120x120mm |

1.5-4.0mm |

1.5-3.0mm |

20-60m/min |

132KWx2 |

400KW |

|

RT115 |

48-127mm |

40x40-100x100mm |

1.5-5.0mm |

1.5-4.5mm |

20-60m/min |

160KWx2 |

400KW |

|

RT115 to 165 |

48-165mm |

40x40-130x130mm |

1.8-5.0mm |

1.8-4.0mm |

20-60m/min |

160KWx2 |

400KW |

|

RT165 |

50.8-165mm |

40x40-130x130mm |

2.0-6.0mm |

2.0-5.0mm |

15-50m/min |

200KWx2 |

500KW |

|

RT165 to 219 |

76-219mm |

60x60-170x170mm |

2.0-6.0mm |

2.0-5.0mm |

15-50m/min |

220KWx2 |

500KW |

|

RT219 |

89-219mm |

70x70-170x170mm |

2.5-8.0mm |

2.5-6.0mm |

12-35m/min |

250KWx2 |

600KW |

|

RT273 |

102-273mm |

80x80-210x210mm |

2.5-10.0mm |

2.5-8.0mm |

10-30m/min |

250KWx2 |

800KW |

|

RT355 |

219-355mm |

170x170-280x280mm |

4.0-12.0mm |

4.0-10.0mm |

10-30m/min |

250KWx2 200KWx2 |

1200KW |

Key words:

ERW Carbon Steel Tube Mills

ERW Tube Mills

Tube and Profile Lines

Related Products

Get a Free Product Quote