Products

Heavy Duty Cut to Length Line

※ High Automaticity! Customization!

Category:

Product Parameters

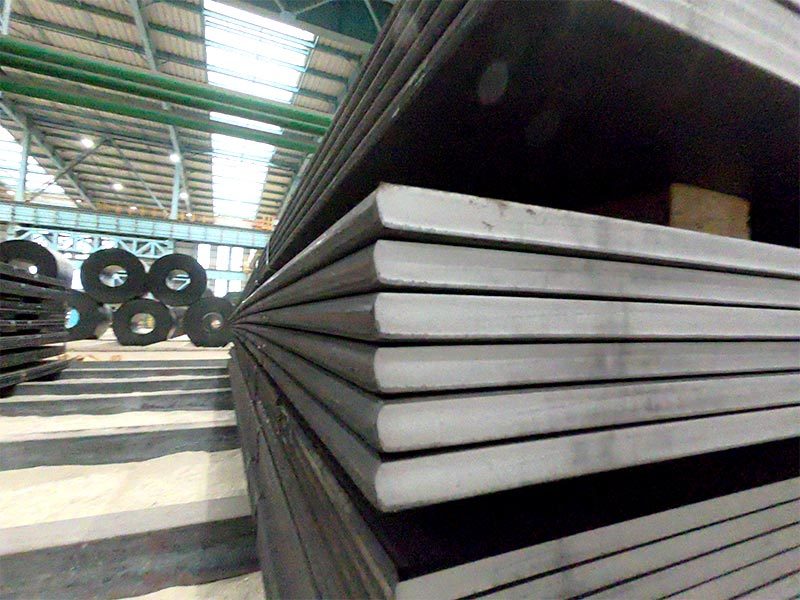

Heavy-duty, Heavy gauge cut-to-length plate lines are designed to produce the most accurate lengths and perfectly flat sheets or plates.

|

|

Finsihed Sample 2 |

|

|

The cut to length (CTL) line is applicable for the material hot rolled carbon steel, for thickness up to 25mm, width up to 2500mm and coil weight up to 35T. It is mainly composed of the decoiler, pinch roll and leveler, length controller, shearer and stacker etc., accompany of the feeder, side guider, loop bridge etc. In Looping Pit Lines, the material never stops in the entry section of the line. Continuous High-Speed Cut-to-Length Lines are equipped with dynamic shears (moving shear / track cutting shear) designed to cut the material at line speed, thus allowing the strip to move continuously. The CTL products can be used in a variety of different types of plants: steel mills, metal service centers, automotive plants etc. |

Advantages

※ Each part working is controlled by PLC with high automaticity and good reliability.

※ DC digital speed control system adopted for fast response speed, good dynamic and static characteristics,

※ High precision encode to effectively control the measuring precision and running speed of the plate.

※ The shearing length and quantity is measured and displayed automatically.

※ It has the function of emergency stop and alarm if any accident.

※ Brush/vacuum Dust Collector for material surface finishing

※ “Lift Type” Conveyors for continuous running of entry section

※ Tracking cutting/moving cutting shear for non-stop.

※ Start-stop shear can be equipped as customized.

※ Simple stacker and auto stacker can be chosen.

※ Edge trimming device can be chosen.

|

|

Moving Shear |

Auto Stakcer |

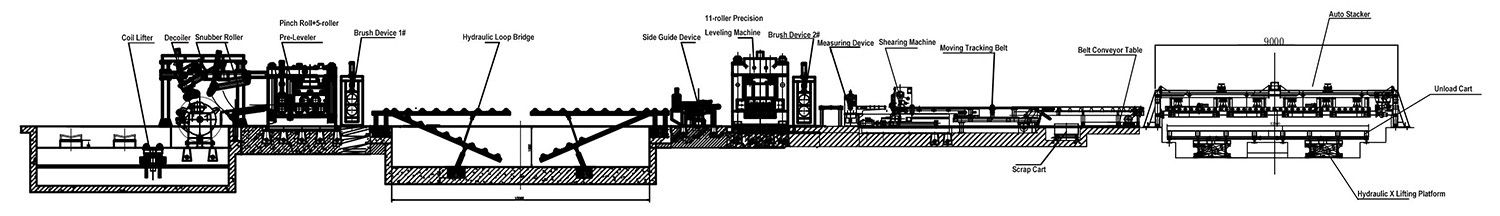

Process Flow

Storage Platform → Coil Lifter → Decoiler → Snubber Roller → Pinch Roll + Pre-Leveler → Brush Device 1# → Loop Bridge → Side Guide → Prevision Leveler → Brush Device 2#→ Measuring Device → Shearing Machine → Belt Conveyor → Auto Stacker+ X lifting platform + Unload Cart

Technical Parameter

|

Material |

Hot rolled steel coil |

|

Thickness Range |

1-4mm; 2-6mm; 2-8mm; 2-10mm; |

|

Width Range |

1600 / 1850/ 2000/ 2200 / 2500mm |

|

Coil Weight |

20 / 25 / 30 / 35 T |

|

Cutting Length |

6m;8m;12m |

|

Working Speed |

0~18m/min |

Key words:

Coil Processing Lines

Cut to Length Line

Heavy Duty Cut to Length Line

Related Products

Get a Free Product Quote